COLD SHOULDER

Cold shoulders of roads, frozen ice around bases of signs, worksites difficult to access, brutally cold winds and temperatures, hazardous driving conditions for deliveries…all these things and more make winter a hard time for many sign shops around Staunton, Virginia, and for that matter, across the Shenandoah Valley. Yesterday, I took advantage of a day when temperatures rose above the freezing point for the first time in many weeks, and installed two signs; one in Augusta County and one in the City of Staunton.

PLAYING IT SAFE

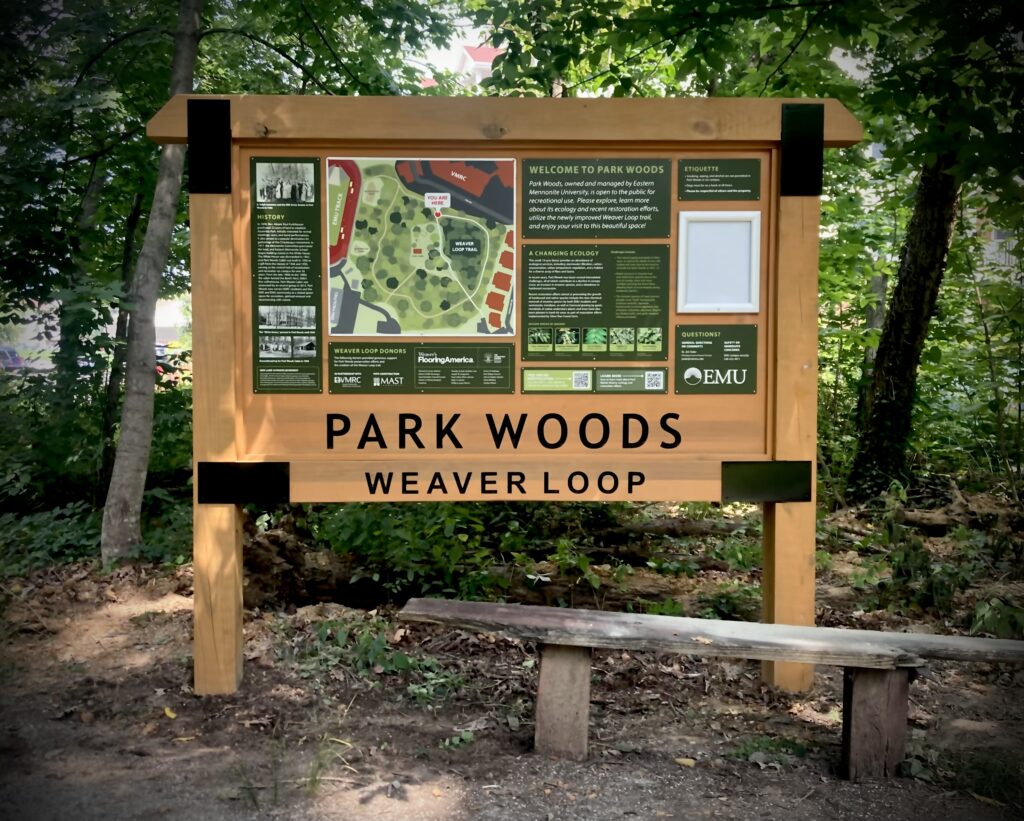

Trying to safely place a step ladder on solid ice can be a big challenge! Once I had my ladder secured, I was able to lift, hold, and fasten two printed ACM panels to a pair of existing PVC posts for a new customer who operates an appraisal business nearby. I made the custom 6MM thick Aluminum Composite Material (ACM) signs in my shop near Middlebrook. Taking the supplied vector artwork from the customer, I was able to digitally print the high-performance 3M vinyl and overlay it onto the ACM.

COLD INSIDE AND OUT

Not only are the temperatures cold outdoors, but they are equally chilly inside my small workshop. As I prepared and applied the 3M laminate to the ACM on the shop tables, I was careful to heat up the material to prevent any unwanted cracking as I squeegied out the air bubbles produced during normal application. The thing I like most about the 3M vinyl product is the way it goes down. When temperatures are normal out in the shop, the vinyl films are applied effortlessly without any application fluid or heat guns needed. But in the cold conditions, I have to be extra careful that things are working out as they should.

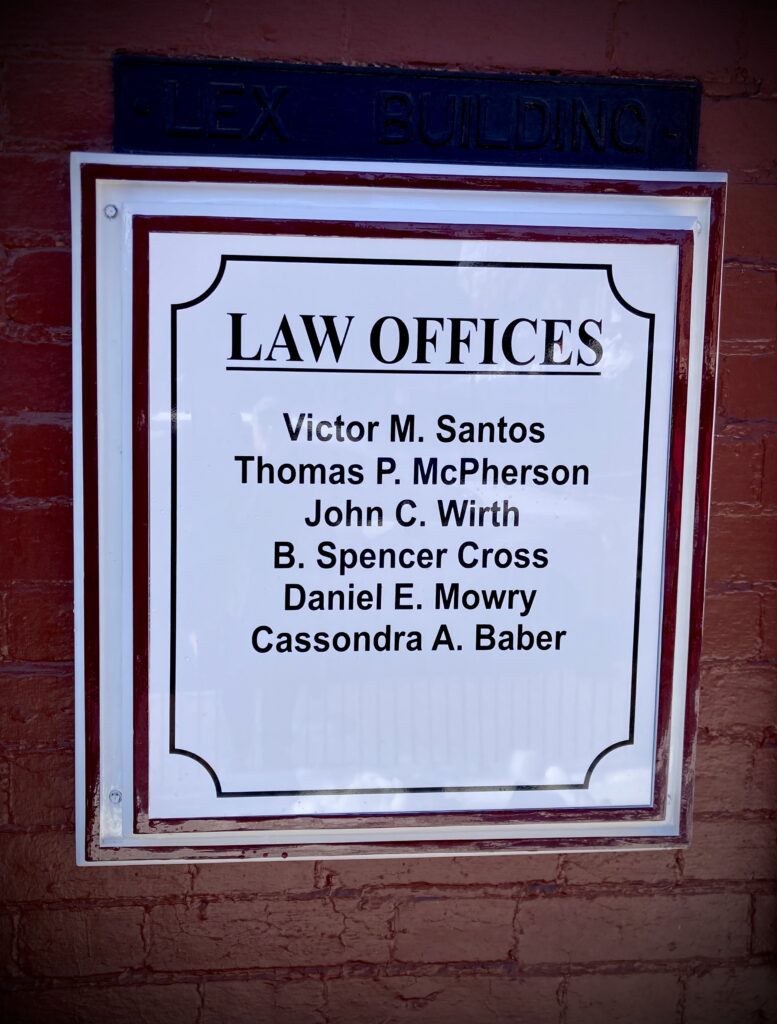

While I was applying the graphics to the ACM, a fresh coat of paint was drying on a custom wood sign for a local law firm. The attorney’s office administrator had called me to update the names of the attorneys there, and renovate the wooden sign that was installed at a historic Staunton property. Due to the temperatures, the drying time took a little longer than normal.

Once the paint dried, the new metal sign was inserted with the updated names, and I loaded up the delivery truck to conduct the two installations out in the cold, cold world. The roads had been reasonably clear for a few weeks, but parking was always a concern, as was walking around on the slippery walks and roadways. I successfully installed the signs, cleaned everything off, then gratefully stopped by the local McDonald’s drive-thru for a nice cup of hot chocolate. A great way to end a cold and icy day of sign installations in the Shenandoah Valley!

THANK YOU LORD

“Dear Lord, thanks for all my projects today and all those currently in my sales funnel, but if it be Your will, please bring the warmer weather and melt all this snow,” I prayed as I left the fast-food establishment. Just then I looked over to my right to see a plump young robin in a patch of brown grass between some huge piles of snow. “Thank you Lord for giving me hope,” I whispered, knowing spring was just around the corner!

Mark Hackley owns and operates Augusta Sign Company, Serving Staunton and Waynesboro, VA

540-943-9818